Revolutionizing Manufacturing with AI-Powered Video Analytics

Executive Summary

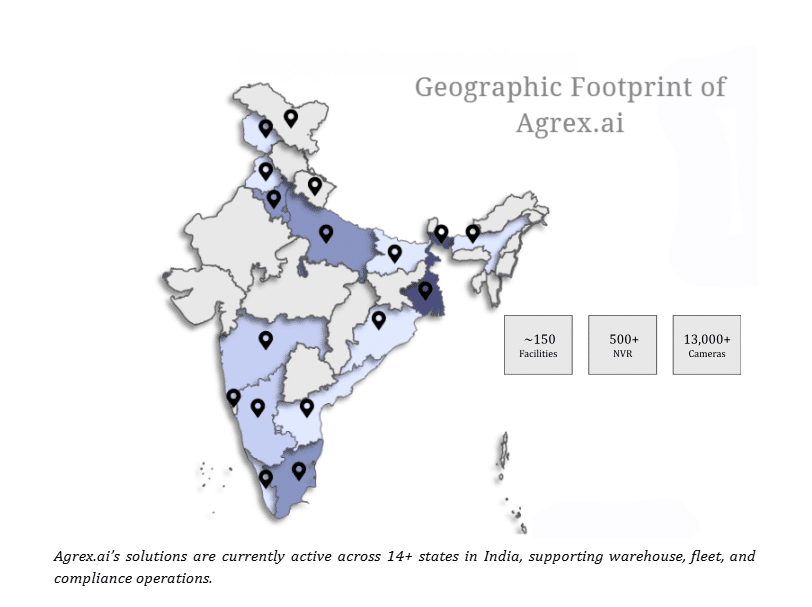

In a global manufacturing environment defined by fierce competition and rising consumer expectations, the need for operational excellence has never been greater. Agrex.ai’s sophisticated AI video analytics platform addresses this challenge head-on, enabling manufacturers to transition from a reactive, manual monitoring model to a proactive, data-driven one. This detailed case study illustrates how a forward-thinking manufacturing client leveraged Agrex.ai’s technology to not only solve critical operational issues but also to fundamentally redefine its production processes, resulting in significant and quantifiable improvements across key performance indicators. By harnessing manufacturing video analytics, the client gained real-time visibility into line performance, worker safety, and compliance adherence. This empowered leadership with actionable insights, minimized downtime, and created a scalable blueprint for sustainable manufacturing excellence.

Market Trend & Context: The Inevitable March of Smart Manufacturing

The manufacturing industry is in the throes of its fourth industrial revolution, or Industry 4.0, where connected and intelligent technologies are transforming factories into smart, data-driven ecosystems. This wave is accelerating, and “manufacturing video analytics” is becoming a pivotal capability that turns passive surveillance infrastructure into active intelligence tools.

Some of the most compelling trends and facts:

The global smart manufacturing market was valued at around USD 349.8 billion in 2024, and is expected to nearly double to approximately USD 790.9 billion by 2030, growing at a CAGR of about 14%.

The industrial AI market (which underpins video analytics) reached USD 43.6 billion in 2024, and is forecasted to grow at ~23% CAGR to reach USD 153.9 billion by 2030.

In a recent Deloitte survey, 57% of manufacturers already use cloud computing, and the same share use data analytics; 46% are using Industrial IoT (IIoT), and 42% are leveraging 5G at the facility or network level.

There is a shift from manual, reactive monitoring to predictive and real-time decision-making; companies are investing more in AI/ML, generative AI, and edge computing to enable rapid detection of anomalies, safety violations, or inefficiencies.

Key drivers reinforcing this transformation:

Data-Driven Decision Making

Manufacturers are moving beyond intuition. With tools like manufacturing video analytics, insights from video feeds (worker behavior, line stoppages, safety violations) feed directly into dashboards, enabling real-time corrective actions and long-term trend analysis.

Hyper-Personalization & Mass Customization

Consumers are demanding more variety, faster delivery, and higher quality. Flexible production lines, modular machinery and smarter monitoring (including video analytics) help adjust workflows dynamically to accommodate smaller batches, variant products, or frequent changeovers.

Elevated Standards for Safety & Compliance

Regulations and stakeholder expectations (employees, customers, insurers) push for near zero-harm environments. Manufacturing video analytics contributes by continuously monitoring SOP adherence, detecting unsafe practices, ensuring protective gear is used, tracking physical distancing or cleanliness where relevant, etc.

The Power of Untapped Data

Many factories have cameras and sensors in place already—but much of that video stream remains unused. There is growing recognition that this untapped visual data, once processed with AI/ML, becomes a goldmine: enabling predictive maintenance, quality assurance, security, and efficiency improvements with little incremental hardware investment.

Challenges for Agrex.AI: Paving the Way for a New Era

While the market is ripe for innovation, Agrex.AI, as a pioneer in the space, faces unique hurdles:

- Proving ROI Beyond the Buzz: The challenge of moving beyond “AI hype” to provide clear, demonstrable financial returns that justify the initial investment.

- Harmonizing with Legacy Infrastructure: Integrating a state-of-the-art AI platform with the diverse and often outdated hardware of a traditional factory.

- Building Trust & Ensuring Privacy: Navigating the ethical complexities of video monitoring and guaranteeing the privacy and security of sensitive operational data.

- Maintaining Precision at Scale: The necessity for algorithms that are highly accurate and adaptable to the dynamic and unpredictable nature of a real-world factory floor.

The Agrex.AI Advantage: Innovation Beyond the Obvious

Agrex.AI implemented an AI manufacturing video analytics system tailored to the client’s specific needs. The solution comprised the following components:

- Camera Network Deployment: Agrex.AI strategically deployed a network of high-definition cameras throughout the manufacturing facility to provide comprehensive coverage of production lines, storage areas, and critical zones.

- AI-Driven Video Analysis: Advanced AI algorithms were integrated into the system to analyze live video feeds in real-time. These algorithms were trained to detect anomalies, identify potential hazards, monitor production metrics, and track the movement of assets and personnel.

- Data Integration and Visualization: The insights generated by the AI algorithms were integrated with existing data sources, including production databases and IoT sensors, to provide a holistic view of operations. Customized dashboards and reports were developed to visualize key performance indicators (KPIs) and trends.

- Automated Alerts and Notifications: The system was configured to generate automated alerts and notifications in case of deviations from predefined norms or safety protocols. This enabled proactive intervention and timely resolution of issues.

See it live in your factory's footage

The Agrex.AI Suite for Manufacturing: Modules in Action

Agrex.AI’s platform is a powerful toolkit for the smart factory, broken down into specialized modules designed to target critical areas of operation.

1. Safety & Compliance

This suite of modules goes beyond simple surveillance, acting as a real-time safety partner for every worker. Manufacturing video analytics transforms existing cameras into vigilant guardians that help prevent accidents before they happen.

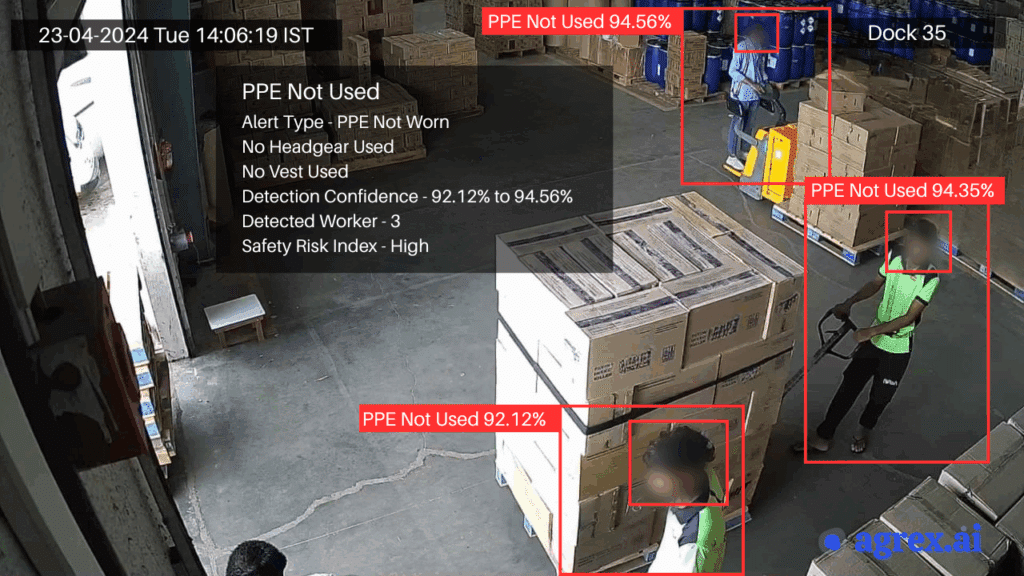

PPE

Compliance

This module uses computer vision to automatically detect whether workers are wearing all required Personal Protective Equipment (PPE) in designated zones. It can identify specific items such as face shields (while welding), safety goggles, hand gloves, safety masks, and safety shoes.

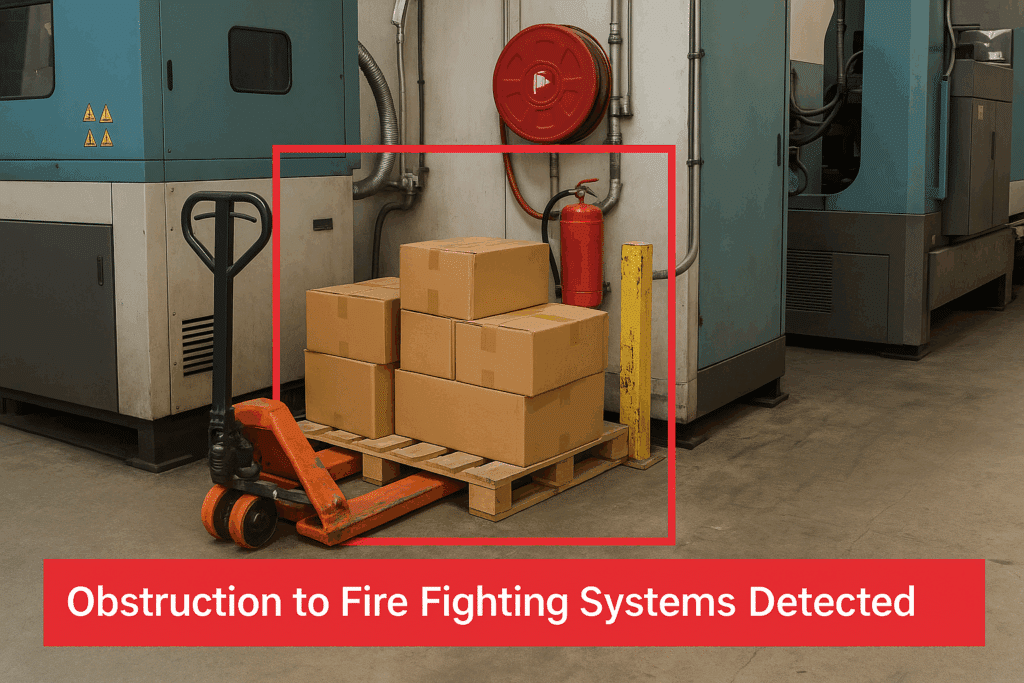

Obstruction to Fire Fighting Systems

The module is trained to recognize fire extinguishers, emergency exits, and hose reels. It issues an immediate alert if a person, equipment, or material is obstructing a fire fighting system, ensuring emergency pathways are always clear.

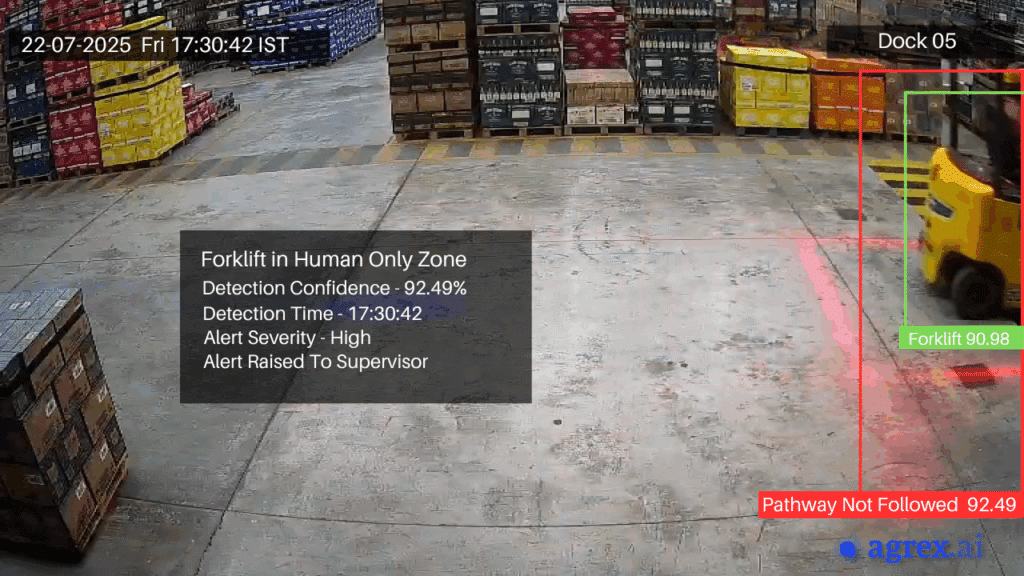

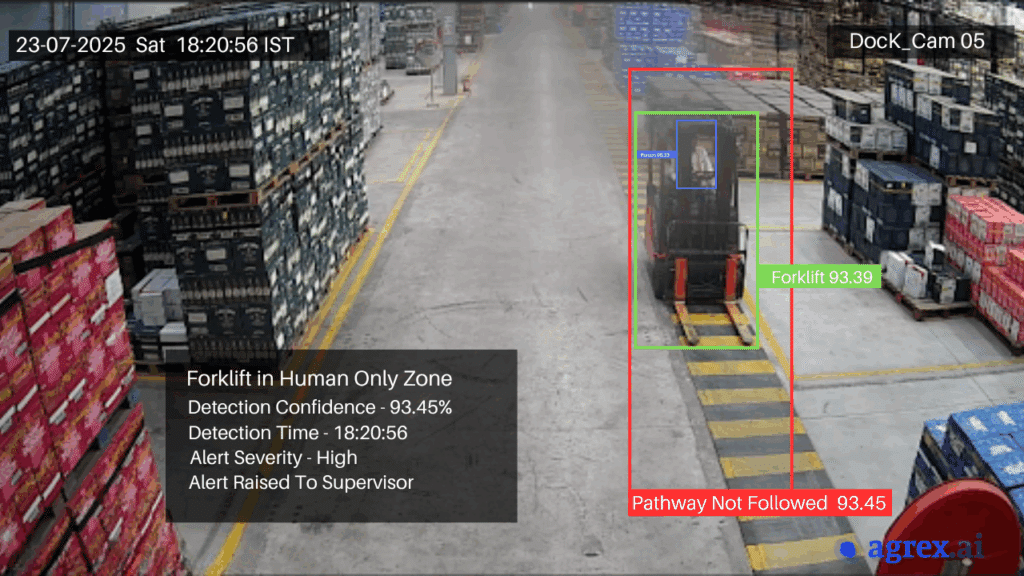

Forklift in Human Passage Way

This dual-purpose module monitors dedicated pathways for both vehicles and personnel. It identifies if a forklift deviates into a pedestrian-only aisle or if any material (Material in Aisle space) blocks a designated route for forklifts or human movement.

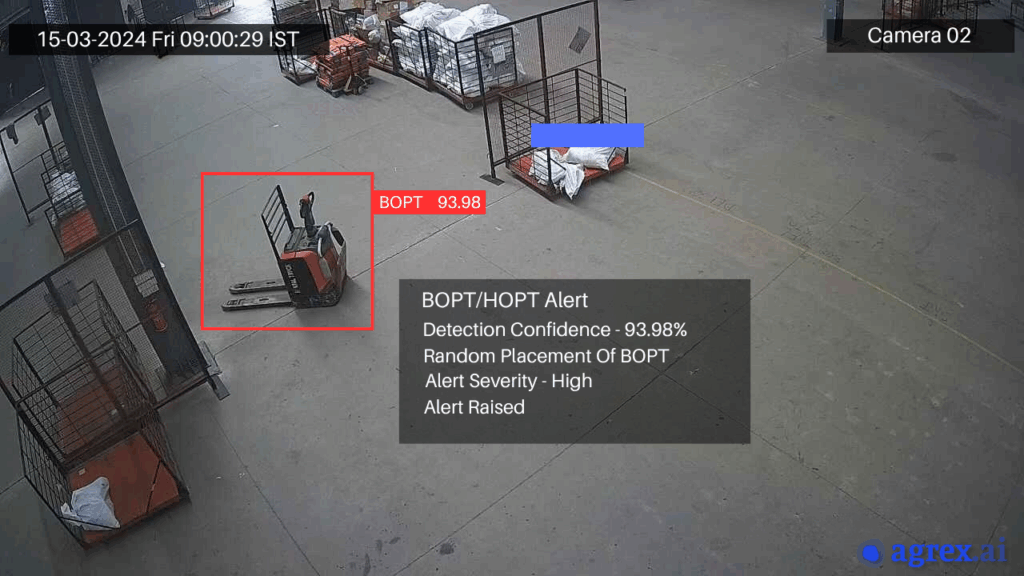

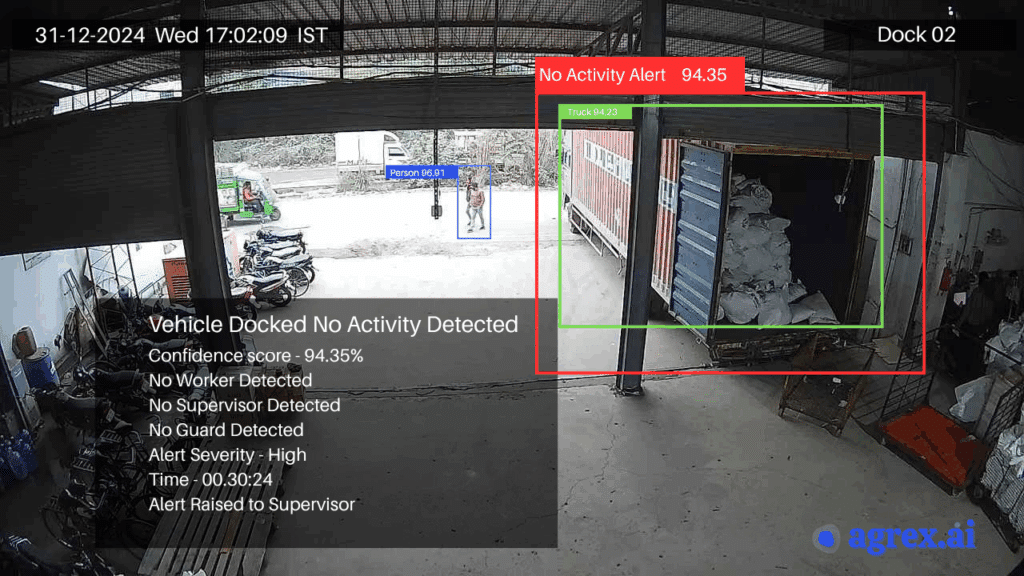

Random Parking of BOPT / HOPTR

The system identifies when forklifts, pallet jacks, or trucks are left parked in non-designated or unsafe areas. This includes monitoring for wrongly parked trucks at the dock.

2. Operational Efficiency & Workflow Modules

These modules provide deep insights into the flow of operations, enabling factory managers to identify and rectify inefficiencies, reduce waste, and maximize productivity.

Pathway not Followed

This module tracks the movement patterns of both people and equipment. It compares actual movement against pre-defined, optimized pathways to identify inefficiencies, unnecessary detours, or redundant motion. By highlighting deviations from the ideal path, this system helps to streamline workflows and reduce wasted effort, leading to significant gains in productivity.

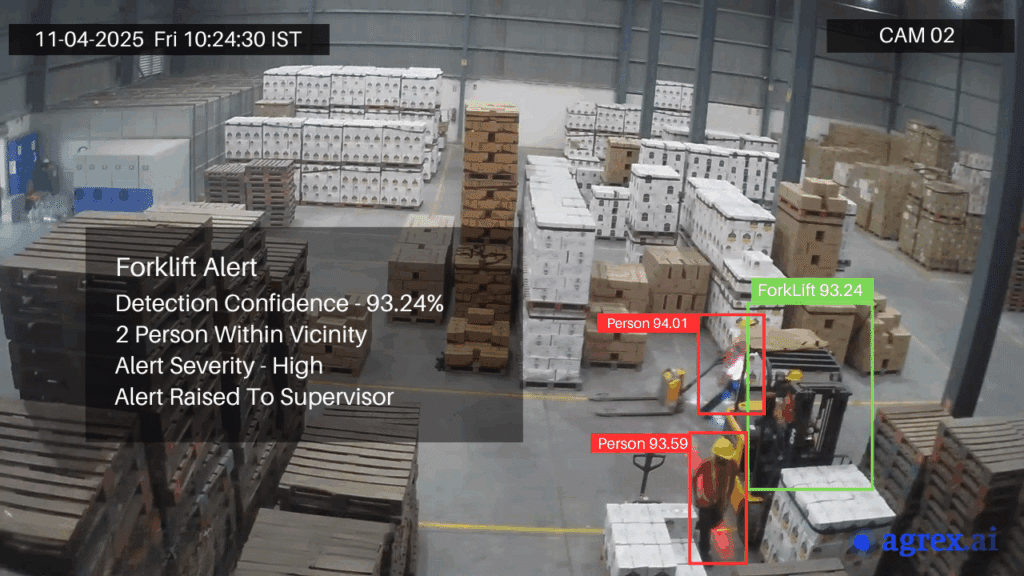

Forklift Operator and Human Detection

This foundational module povides real-time counts and location data for both personnel and equipment. This real-time visibility enables effective resource allocation and enhances on-site safety protocols. The precise location data is essential for optimizing workflows and responding to emergencies with speed and accuracy.

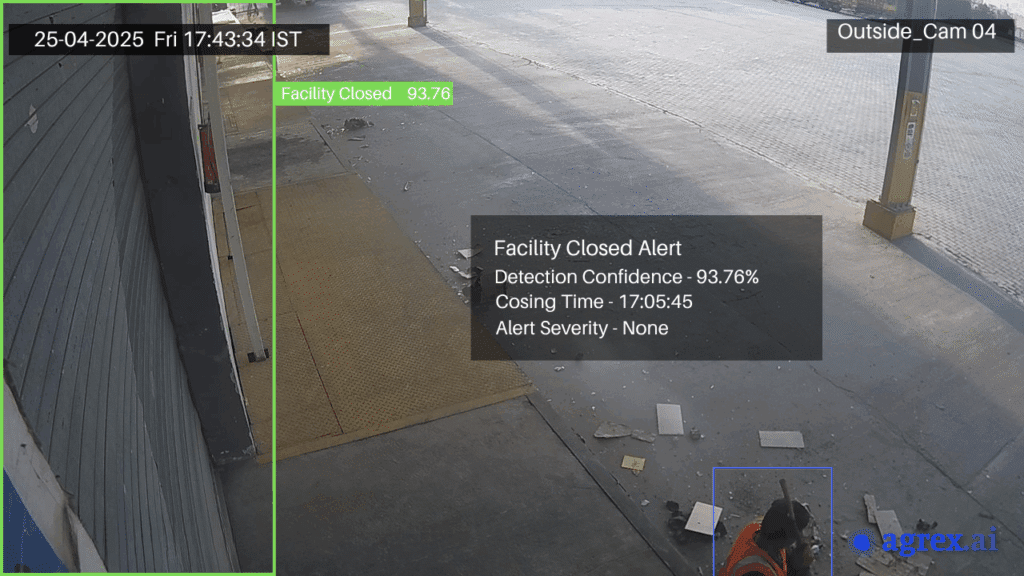

Opening / Closing Time & Dock In / Out Time

This module provides real-time visibility into warehouse logistics by automatically logging precise timestamps for door activity and truck movements. By eliminating manual data entry, it ensures the accuracy of arrival and departure times, helping to optimize supply chain efficiency.

Vehicle Turnaround Time

By tracking a vehicle from arrival to departure, the system can measure how long a truck waits to be serviced (Vehicle Wait Time) and the total time it spends on site (Vehicle Turnaround Time). This is achieved through the use of ANPR (Automatic Number Plate Recognition) cameras, which capture the vehicle’s entry and exit times.

3. Quality & Behavior Monitoring Modules

These modules focus on upholding quality standards and identifying behaviors that can lead to product damage or a compromised work environment.

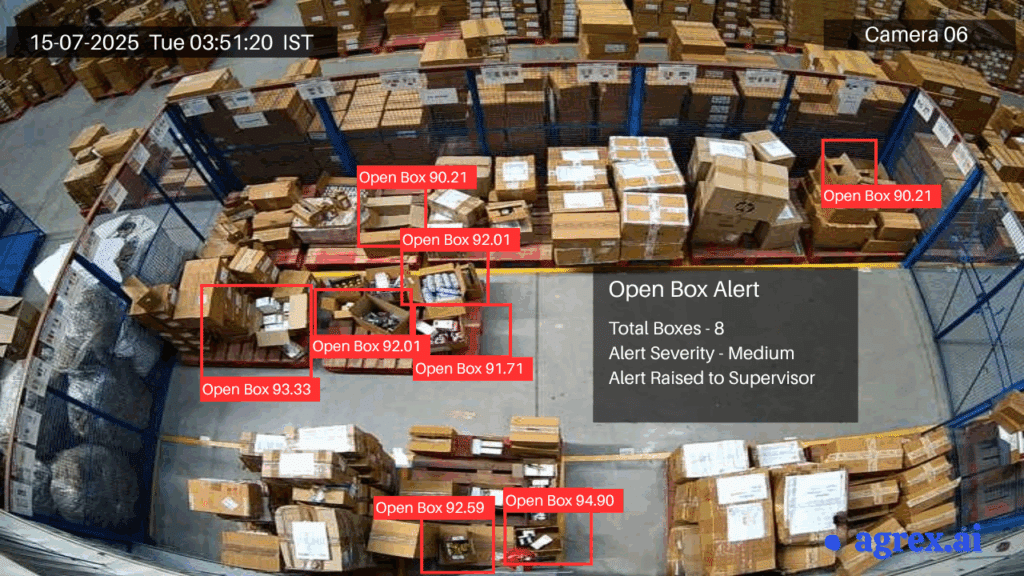

Open Box Detection / Damaged Box

The AI is trained to recognize defects and damage to packaging, such as a tear, a dent, or an open box. It can flag these issues in real-time, preventing a damaged product from moving to the next stage.

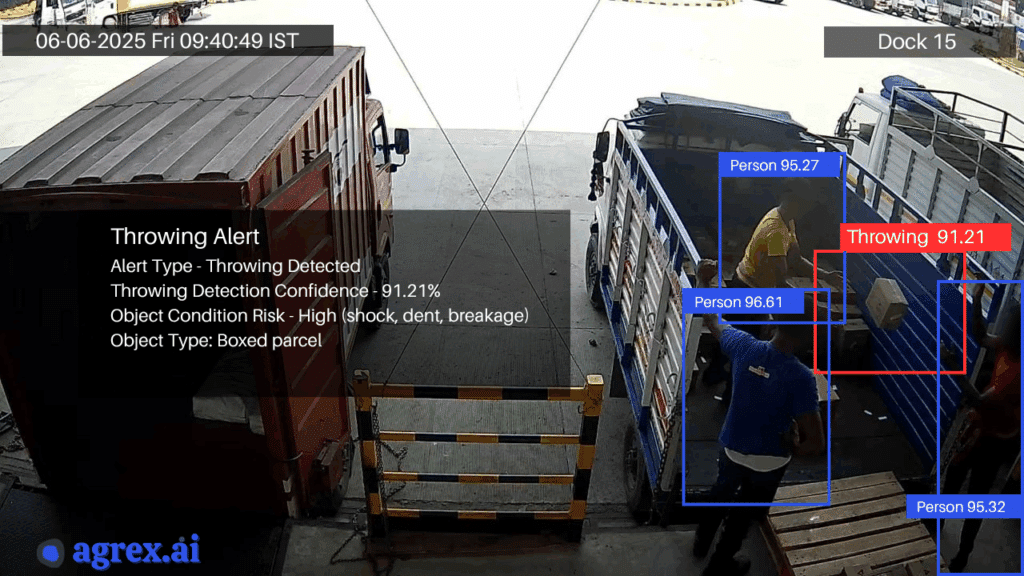

Throwing Package While Loading/Unloading & Uncovered Truck

These behavioral analytics use cases detect improper handling of products, such as throwing packages, and also check for security and safety issues like an uncovered truck at the dock.

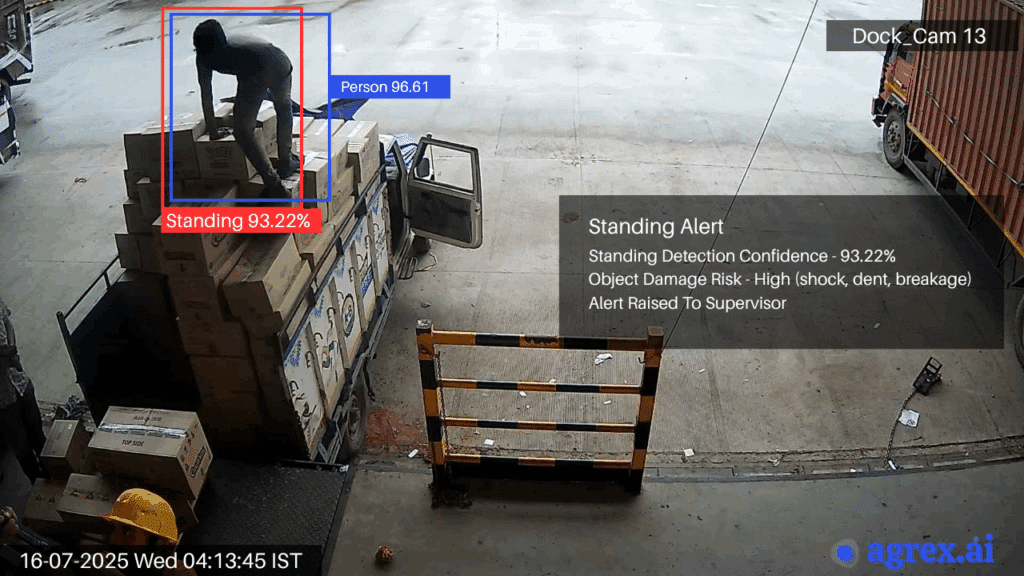

Sitting/Standing on Box & Loaders Sleeping on Bays

The system can alert a supervisor to unproductive behavior, such as a worker sitting on a box they should be moving, or a loader who is resting when they should be working. This helps to ensure a consistent work ethic and a more productive environment for everyone.

The Transformative Impact: A Partnership for Sustainable Growth

The implementation of Agrex.AI’s suite delivered a profound and quantifiable transformation for a major manufacturing client. By leveraging manufacturing video analytics, the company fundamentally changed its operational model from reactive to proactive, achieving significant and measurable gains across its facilities.

- Improved Operational Efficiency: By providing real-time insights into production processes, the manufacturing video analytics system enabled the client to identify and address inefficiencies promptly. This led to significant improvements in production throughput and resource utilization.

- Enhanced Safety and Compliance: The automated monitoring and detection capabilities of the manufacturing video analytics system helped ensure strict compliance with safety regulations and proactively prevent accidents. Proactive alerts and notifications enabled a rapid response to potential hazards, fostering a safer work environment for all personnel.

- Optimized Resource Allocation: The client was able to optimize the allocation of resources, such as manpower and machinery, based on real-time demand and production requirements. This resulted in significant cost savings and increased overall productivity.

- Data-Driven Decision Making: The integration of AI-driven insights with existing data sources empowered the client to make informed decisions based on comprehensive and up-to-date information. This facilitated strategic planning and long-term optimization of operations.

Key Performance Indicators (KPIs) Improved by Manufacturing Video Analytics

| KPI | Improvement | Business Benefit |

|---|---|---|

| Package Mishandling | ↓ 40% | AI-powered monitoring reduces product damage and waste on the production line, cutting rework costs. |

| Pilferage | Major Reduction | AI asset tracking prevents the loss of valuable tools and equipment, improving accountability and reducing replacement costs. |

| PPE Compliance | ↑ 64% → 91% | Automated safety monitoring ensures consistent adherence to PPE protocols, drastically reducing on-site accidents and improving regulatory compliance. |

| Production Line Cycle | ↓ 18% | Workflow analytics identifies and eliminates bottlenecks, improving material flow and increasing throughput on the assembly line. |

| Machine Idle Time | ↓ 30% | Real-time AI alerts on machine inactivity enable prompt intervention, maximizing machine uptime and boosting overall production. |

| Floor Space Utilization | Improved | AI-powered layout analysis optimizes the placement of machinery and materials, maximizing factory floor space for production and storage. |

Conclusion:

The Agrex.AI case study is more than a story of technological implementation; it’s a blueprint for the future of manufacturing in the era of Industry 4.0. By providing a powerful yet practical and tailored solution, Agrex.AI proves that harnessing video analytics is not just an option—it’s an imperative for any business aiming to achieve tangible, bottom-line results and secure a competitive edge. The ability to transform passive CCTV data into actionable intelligence empowers manufacturers to create smarter, safer, and more efficient factories that are built to thrive in a complex and competitive market.

Eliminate the 'What Ifs': Schedule a Live Safety & Efficiency Preview

Frequently Asked Questions (FAQ) – Manufacturing Video Analytics

Manufacturing video analytics uses AI and machine learning to automatically analyze video streams from cameras in a factory. Instead of just recording footage for later review, the system instantly detects objects, people, and events, identifying patterns and anomalies to provide real-time, actionable data. It transforms passive cameras into an intelligent, always-on sensor network.

Traditional CCTV is a reactive tool; it records footage that is reviewed by a human after an incident occurs. Manufacturing video analytics, on the other hand, is a proactive tool. It acts as an intelligent layer on top of your existing cameras, processing video in real time to generate alerts, insights, and data. It doesn’t just show what happened; it explains why, and helps prevent future issues.

The core benefits fall into three categories:

- Enhanced Safety: It automates compliance checks for safety protocols like PPE usage, detects unsafe behaviors, and flags potential hazards instantly. This helps prevent accidents and reduce the risk of injury.

- Improved Efficiency: The system provides deep insights into workflows, identifies bottlenecks, tracks asset utilization, and automates tasks like counting products on a conveyor. This optimizes processes, reduces waste, and boosts productivity.

- Better Quality Control: AI algorithms can inspect products for defects like cracks, scratches, or misalignments with a level of accuracy and speed unmatched by human inspectors. This ensures only high-quality products are shipped, minimizing recalls and rework costs.

No, in most cases, you don’t. A significant advantage of modern manufacturing video analytics solutions is their ability to integrate seamlessly with a factory’s existing camera infrastructure. The AI software can be deployed to analyze the feeds from standard industrial or security cameras, making the solution both cost-effective and easy to implement.

Data privacy is a critical concern. Solutions are designed with built-in privacy measures, such as blurring or anonymizing faces and personally identifiable information. The system focuses on analyzing behaviors and objects, not individuals. Additionally, all video data and insights are typically secured with robust encryption and access controls, ensuring compliance with relevant data protection regulations.