How Logistics Video Analytics Boosts Your Supply Chain

Executive Summary: The Dawn of a Smarter Supply Chain

The global logistics and supply chain industry, the backbone of a multi-trillion-dollar global economy, stands at a critical juncture. Faced with unprecedented challenges—from the explosive growth of e-commerce to persistent labor shortages—traditional operational models are no longer sufficient. This is where logistics video analytics emerges not just as a security tool, but as a transformative solution for operational excellence.

This comprehensive report outlines how our innovative platform, Agrex.ai, is addressing these pressing industry challenges. By transforming existing CCTV infrastructure into a powerful source of real-time, actionable intelligence, we are enabling logistics companies to achieve a level of visibility, efficiency, and safety that was previously unattainable. The following sections will delve into the market trends shaping the industry, the specific challenges faced by logistics leaders, and how our solution provides a clear competitive advantage, validated by industry data and real-world case studies.

I. The Market Context: A Sector in Rapid Transformation

The logistics and supply chain landscape is in a state of flux, driven by several powerful and interconnected forces. To understand the value of video analytics, one must first appreciate the macro-level context that is redefining the rules of the game.

The Challenge: Operational Blind Spots in Modern Logistics

The problems stemming from these market trends manifest as clear, quantifiable challenges within a typical logistics facility. These are the pain points that keep logistics managers up at night.

1. The E-commerce Surge:

The global e-commerce logistics market is projected to reach over $1.9 trillion by 2032, fueled by consumer demand for faster delivery. This growth puts immense pressure on fulfillment centers to operate with zero-error speed, creating bottlenecks and increasing the risk of costly delays and mistakes.

2. The Labor Crisis:

The U.S. logistics sector alone faces a projected shortfall of over 2 million workers by 2025. This scarcity drives up labor costs and forces companies to find new ways to maximize productivity. As a result, supply chain leaders are increasing their tech budgets to fill labor gaps and boost efficiency.

3. The Need for Visibility and Resilience:

Supply chain leaders recognize that digital transformation is key to building an integrated and resilient supply chain. Many businesses still operate with fragmented data and “blind spots,” unable to track goods in real time or anticipate disruptions.

4. The Imperative of Safety:

The logistics industry has one of the highest rates of workplace injuries. A manual approach to safety monitoring is no longer enough to prevent accidents and costly liabilities. Companies need proactive, real-time solutions to enforce compliance and prevent incidents before they occur.

II. The Challenge: Operational Blind Spots in Modern Logistics

The problems stemming from these market trends manifest as clear, quantifiable challenges within a typical logistics facility. These are the pain points that keep logistics managers up at night.

1. Dock and Yard Management:

The loading dock is the lifeblood of any distribution center. A breakdown here can create a ripple effect of delays and inefficiencies throughout the entire network. The fundamental challenge is a lack of real-time, precise data. Managers often rely on radio calls, manual check-in sheets, and anecdotal evidence to manage truck arrivals and departures. This results in:

Costly Detention Fees:

Carriers charge significant fees for every hour a truck is delayed beyond its scheduled time. These costs can run into the tens of thousands of dollars per month for a large facility.

Yard Congestion:

Without a clear view of dock availability, trucks are left idling, creating traffic jams that hinder the movement of other vehicles and equipment.

Sub-optimal Resource Allocation:

Managers cannot efficiently allocate labor and equipment (e.g., forklift operators) without knowing which docks are busy and which are free, leading to wasted time and resources.

2. Workplace Safety and Compliance:

A logistics facility is a beehive of activity, with forklifts, robots, and human workers sharing space. This high-traffic environment is ripe for accidents. The challenges are not just about preventing incidents but also about ensuring consistent adherence to safety protocols.

Inconsistent PPE Adherence:

Despite company policies, it is a constant struggle to ensure every employee is wearing their hard hat, safety vest, and other required gear in high-risk zones. Manual checks are time-consuming and prone to human error.

The Problem of "Near-Misses":

Many safety incidents are near-misses that go unreported. Without a system to automatically flag these events, companies miss out on valuable data that could prevent future, more serious accidents.

Human Error and Fatigue:

In a fast-paced environment, human operators can make mistakes due to fatigue, distraction, or a simple lapse in judgment. The consequences can be severe.

3. Operational Inefficiencies:

Efficiency is the key to profitability, yet many facilities are operating with a significant portion of their potential unrealized.

Workflow Bottlenecks:

Managers may know a process is inefficient but can’t pinpoint the exact cause. Is it a problem with the layout? A slow-moving piece of equipment? An inefficient picking route? Without data, the answers are guesswork.

Shrinkage and Security Lapses:

Inventory loss due to theft or damage is a major cost center. Traditional surveillance is only useful after an incident has occurred, making it a reactive tool for forensics, not prevention.

Lack of Actionable Data:

Many legacy systems provide raw data without context. A manager might see that productivity is down, but without video-based evidence, they can’t understand why. This leads to delayed decision-making and a cycle of reactive problem-solving.

See it live in your warehouse footage

III. The Solution: Agrex.ai's Video Analytics Platform

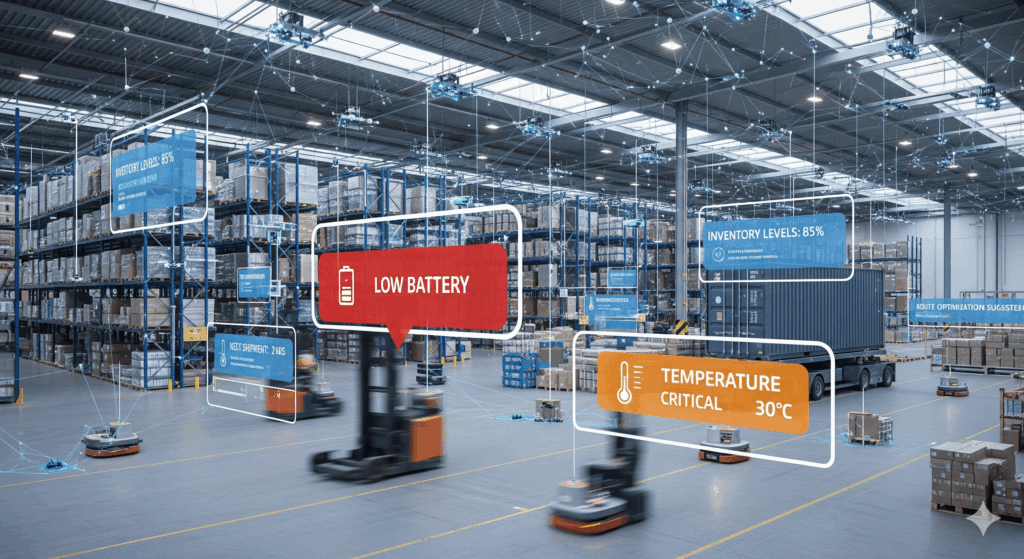

Agrex.ai provides a full-stack, AI-driven solution that directly addresses the core pain points of the logistics industry. By leveraging your existing CCTV cameras, our platform transforms a passive surveillance system into an active operational intelligence hub. The key to our solution is its ability to turn unstructured video data into structured, actionable insights.

How it Works: Our platform uses advanced computer vision and machine learning models, trained on millions of hours of logistics footage, to automatically analyze video streams in real time. The platform identifies specific objects (trucks, forklifts, pallets), events (a truck arriving, a box being dropped), and behaviors (a person entering a restricted area, a safety vest being removed). These insights are then fed into an easy-to-use dashboard and a smart alerting system.

1. Optimizing Dock Management

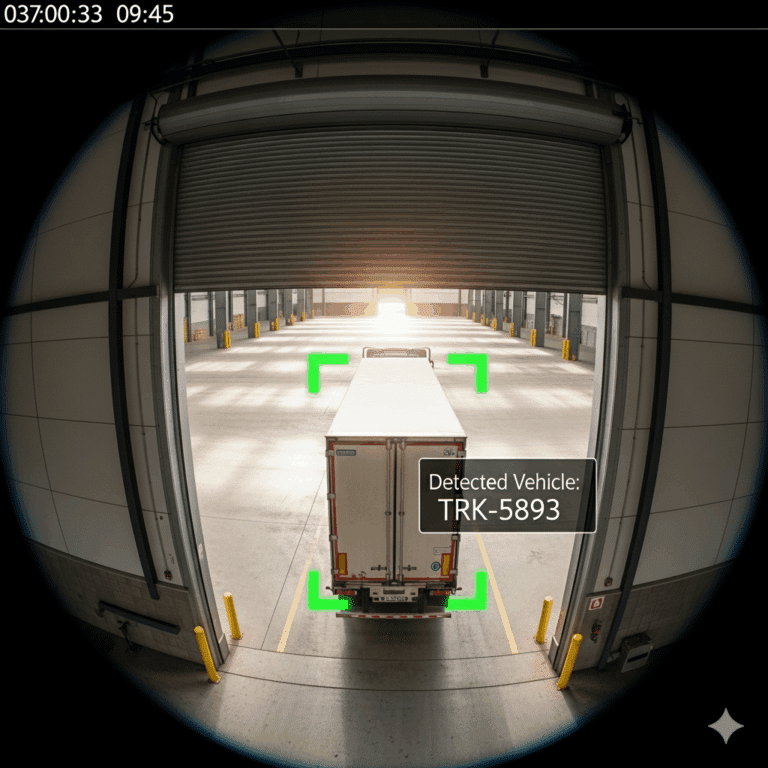

Automated Number Plate Recognition (ANPR):

The system’s AI automatically reads and recognizes the license plates of every vehicle entering and exiting the facility. This provides a unique, unbiased identifier for each truck, eliminating the need for manual data entry and ensuring accurate record-keeping.

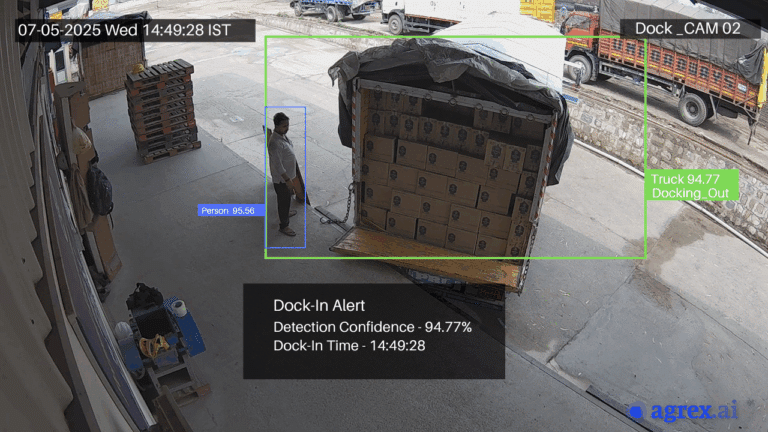

Real-Time Dock In and Dock Out Tracking:

The platform precisely detects the moment a truck pulls into a designated dock (“Dock In”) and the exact moment it leaves (“Dock Out”). These precise time stamps are the foundation for our automated reporting.

Automated Turn-Around Time (TAT) Calculation:

By linking the ANPR data with the Dock In/Dock Out times, the system automatically calculates the total time a truck spends at the dock. This provides an accurate, real-time TAT metric that enables the logistics team to identify and address delays instantly.

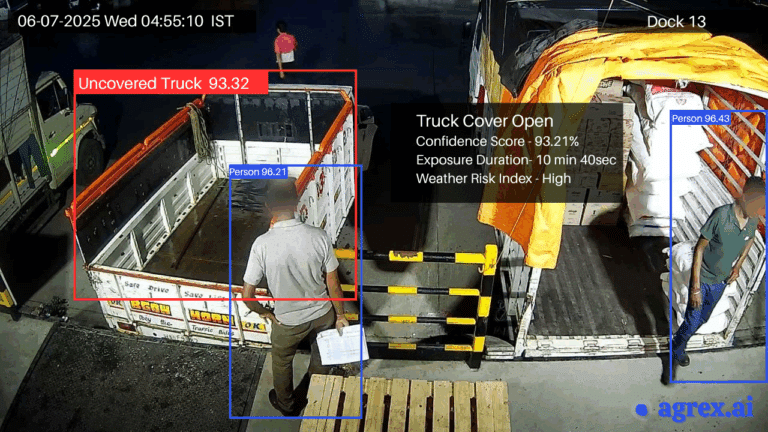

Detection of Uncovered Vehicles:

For facilities that handle specific types of cargo, the AI can be configured to detect if a vehicle, such as a flatbed, is uncovered when it enters or leaves a specific area. This adds a crucial layer of compliance and security, preventing potential cargo damage or security breaches.

Automated Alerts:

If a truck exceeds its scheduled unloading time, or if a discrepancy is detected, the system sends an immediate alert to a supervisor’s mobile device, allowing for swift intervention before the issue escalates. This proactive approach saves time and money.

2. Proactive Safety Monitoring and Incident Prevention

Automated PPE Compliance:

The AI is configured to recognize and verify the use of essential Personal Protective Equipment (PPE) such as hard hats, safety vests, and steel-toed boots. If a worker enters a restricted area without the correct gear, the system can instantly trigger a visual or audible alert, or notify a supervisor, preventing a potential accident before it happens. This can lead to a significant reduction in safety-related incidents, as seen in case studies where similar technology has reduced safety violations by over 60%.

Hazard and Anomaly Detection:

We actively monitor for dangerous behaviors and environmental risks. This includes identifying workers getting too close to machinery, detecting objects left in aisles that could be tripping hazards, and flagging dangerous activities such as objects being thrown or mishandled. Instant alerts enable immediate intervention, preventing near-misses from escalating into serious incidents.

Near-Miss Visibility:

The platform automatically logs and provides video evidence of near-miss events (e.g., two forklifts nearly colliding). By analyzing this data, safety managers can understand the root cause and implement corrective measures to prevent a future accident. A recent study by a competitor highlighted a 1,498% increase in near-miss visibility through similar technology, underscoring the clear impact of AI in this domain.

3. Unlocking Operational Efficiency and Maximizing Asset Utilization

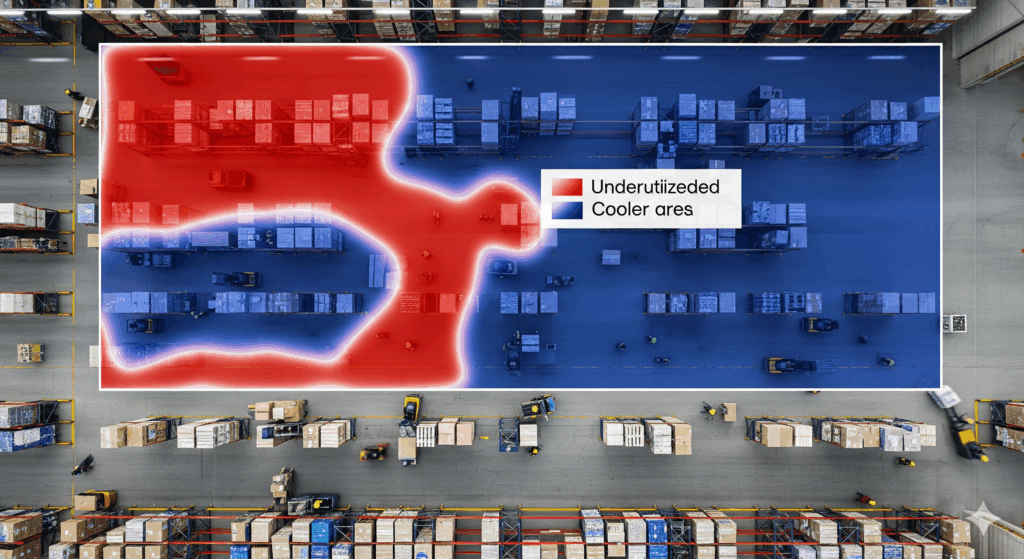

Workflow Bottleneck Identification:

Our AI models can map the movement of forklifts and personnel within a facility. By analyzing these traffic patterns, we generate heatmaps that identify congestion points and underutilized areas. This data is invaluable for warehouse managers looking to reconfigure layouts, optimize picking routes, and reduce travel time.

Automated Productivity Monitoring:

The platform can detect the moment a pallet is placed on a rack or a parcel is scanned, allowing you to track labor productivity automatically and non-intrusively. This provides a fair and objective measure of performance, empowering managers to identify top performers and provide targeted training.

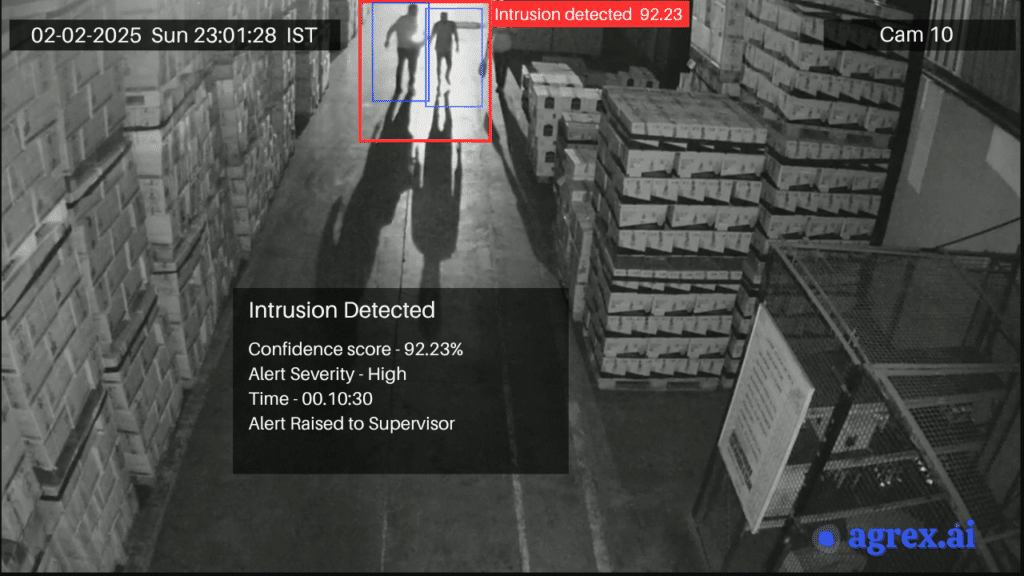

Inventory Security and Shrinkage Prevention:

Our system automatically detects unauthorized parcel opening, pilferage from open boxes, and intrusion in secure zones, even after hours. It also monitors for camera tampering, ensuring your surveillance system is always operational and secure. This proactive approach helps to significantly reduce inventory shrinkage, a major source of loss for logistics companies.

IV. Why Agrex.ai is Different: The Human-Centric AI Advantage

While many companies offer video analytics, Agrex.ai stands out by focusing on a human-centric, seamless, and actionable approach. Our platform is designed to augment human capabilities, not replace them.

1. Capital-Light, Non-Disruptive Deployment

The single greatest barrier to adopting new technology is the high cost of a “rip-and-replace” approach. Our primary differentiator is that we are hardware-agnostic. Our platform integrates seamlessly with your existing CCTV cameras, whether they are new or decades old. This eliminates the need for significant capital expenditure, complex installation processes, and operational downtime. According to PwC, more than 54% of industry leaders believe that digital transformation is key to enabling collaboration with end-to-end supply chain partners (Source: PwC, 2024), and our technology provides the perfect entry point.

2. Intelligent, Actionable Alerts vs. Data Overload

Many video analytics platforms provide a deluge of raw data and complex dashboards that still require a dedicated analyst to interpret. The result is often “data paralysis.” Agrex.ai’s strength lies in its intelligent alerting system. An alert for a safety violation, a long-idling truck, or a security breach is sent directly to the relevant person—be it a manager on their phone or a supervisor on a terminal—with a direct link to the corresponding video clip. This enables immediate intervention and proactive problem-solving, rather than reactive analysis.

3. Unparalleled Customization and Deep Industry Expertise

Our AI models are not static. We have a deep understanding of the unique workflows and challenges of the logistics industry, and we work collaboratively with our clients to tailor our platform to their specific needs. Whether it’s training a model to recognize a new type of safety violation or creating a custom report for a specific KPI, our platform is flexible and adaptable. We are not just selling a product; we are a partner in continuous improvement, and our platform evolves with your business.

4. A Transparent and Secure Architecture

We recognize that data security and privacy are paramount. Agrex.ai is built with a secure, cloud-native architecture that adheres to the highest industry standards. Our system processes video streams in a secure environment and provides clear audit trails, giving you full control and transparency over your data. We ensure that our technology not only enhances your operations but also protects your business.

See it live in your warehouse footage

Conclusion: The Future is Here, and It's Intelligent

The logistics industry is at a crossroads, and the path forward is paved with data and intelligence. The traditional reliance on manual labor, static reports, and reactive oversight is no longer sustainable. Agrex.ai is a testament to the power of AI to transform legacy operations into dynamic, efficient, and secure ecosystems.

By choosing Agrex.ai, you are not just investing in technology; you are investing in a future where your logistics operations are safer, more efficient, and fully optimized by a powerful, yet human-friendly, AI. The tangible benefits—reduced costs, improved safety, and enhanced productivity—provide a clear and compelling return on investment, solidifying the role of logistics video analytics as a critical enabler of the smart supply chain of tomorrow.

Discover how our technology can transform your supply chain by exploring our Logistics Video Analytics Solutions.

Frequently Asked Questions (FAQs) About Agrex.ai Logistics Video Analytics

Logistics video analytics is an AI-powered technology that goes far beyond passive security. While a standard camera system simply records footage for later review, video analytics uses artificial intelligence to actively analyze live video streams in real-time. It identifies, tracks, and reports on specific objects, events, and behaviors, transforming your camera network from a simple security tool into a proactive source of operational intelligence.

The financial benefits are realized through key operational improvements. Our clients see a direct return on investment (ROI) from:

Increased Efficiency: By reducing truck turnaround times and optimizing warehouse workflows, you can handle more volume with the same resources.

Reduced Costs: Decreased detention fees, lower insurance premiums (due to fewer safety incidents), and a reduction in shrinkage directly impact your profitability.

Enhanced Productivity: Data-driven insights help you optimize labor and equipment utilization, ensuring your team is working as efficiently as possible.

One of the core advantages of our platform is that it is hardware-agnostic. We do not require you to “rip and replace” your current cameras. Our solution integrates seamlessly with your existing CCTV infrastructure, which significantly reduces upfront capital expenditure and minimizes operational disruption. Implementation is typically fast and non-invasive.

Absolutely. We understand that every logistics facility is unique. Our AI models are not a one-size-fits-all solution. We work collaboratively with our clients to train the AI to recognize specific operational events, such as a unique type of package handling or a particular safety protocol for your site. This ensures the insights you receive are relevant and actionable.

Our AI acts as a 24/7 safety officer. It can automatically detect a wide range of safety violations, including:

Workers entering a restricted zone without proper Personal Protective Equipment (PPE).

Forklifts getting too close to pedestrians.

Objects left in aisles that could be tripping hazards. By providing real-time alerts, the system enables immediate intervention, helping to prevent incidents before they occur and fostering a more proactive safety culture.

The platform collects data on operational events, such as truck arrival times, idle times, and a log of detected safety violations. We do not collect or store personal identifying information beyond what is necessary for our service. Our system is built with a secure, cloud-native architecture that adheres to the highest industry standards for data encryption and privacy, ensuring your information is protected.

Due to the seamless integration with your existing hardware, our clients typically start to see actionable insights and operational improvements within the first few weeks. The long-term benefits, such as a measurable reduction in costs and safety incidents, become increasingly evident over the first three to six months as you utilize the data to refine your operations.

Any facility that deals with the movement of goods and people can benefit. Our solution is scalable and effective for a wide range of logistics environments, including:

Fulfillment and Distribution Centers

Warehouses and Storage Facilities

Cross-Docking Hubs

Manufacturing and Assembly Plants

We would be happy to show you a personalized demonstration. Please contact us through our website to schedule a live demo with one of our experts. We can discuss your specific operational challenges and show you how Agrex.ai can help you achieve your business goals.