Transform Warehouse Operations with AI-Powered Logistics Video Analytics

Reduce DEPS by 38% and improve compliance to SOPs by 65% – using cameras you already own

Trusted By Leading Brands

100+ Brands

100K+ Cameras

10M+ Alerts

200+ Use Cases

See it live in your warehouse footage

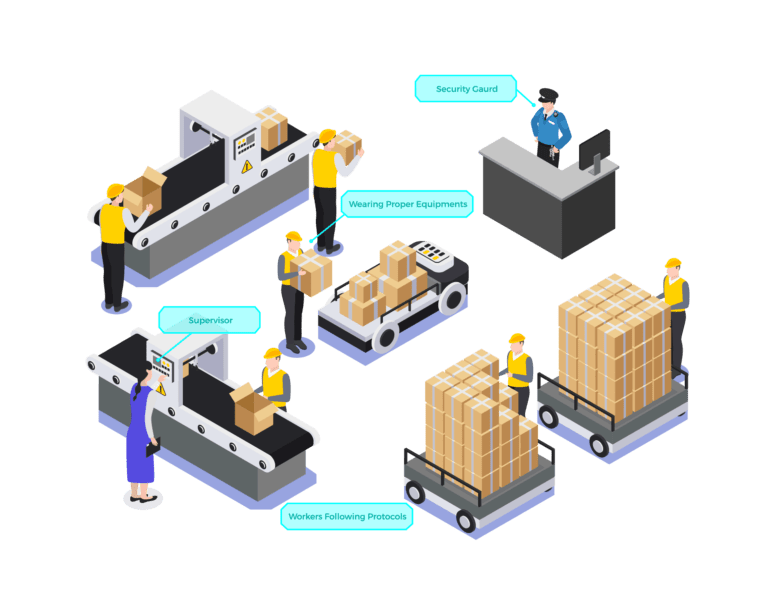

Key Features of Logistics Video Analytics

Quick and Easy Implementation

Plugs into existing CCTV Infrastucture

Get in Touch with Us!

Logistics Video Analytics Makes Your Decisions Data-Driven

Case Study: How a Leading Logistics Operator Boosted Warehouse Productivity and Reduced Losses with AI Video Analytics

Problem

A major pan-India logistics provider managing high-volume warehouse operations faced recurring operational inefficiencies and compliance issues. Despite CCTV coverage, they lacked real-time visibility into violations, improper handling, and safety breaches.

Key operational pain points included:

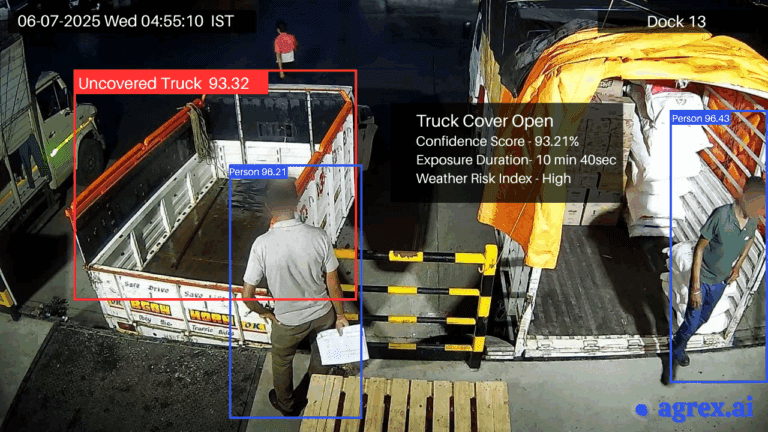

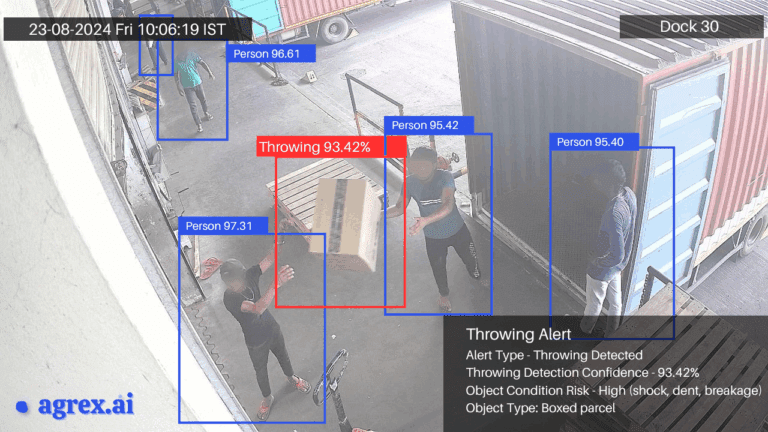

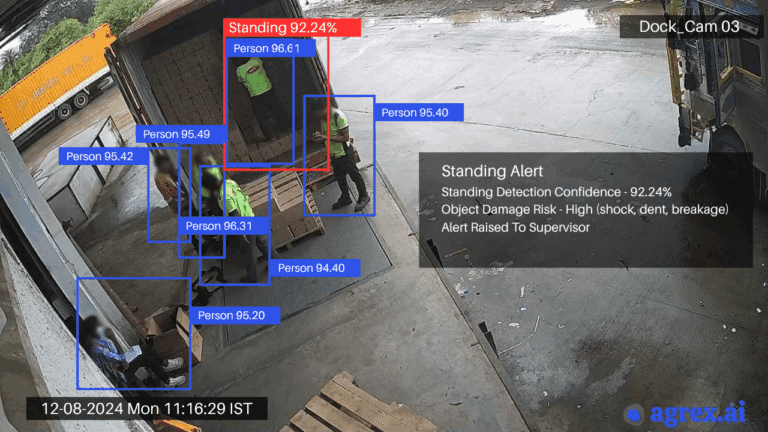

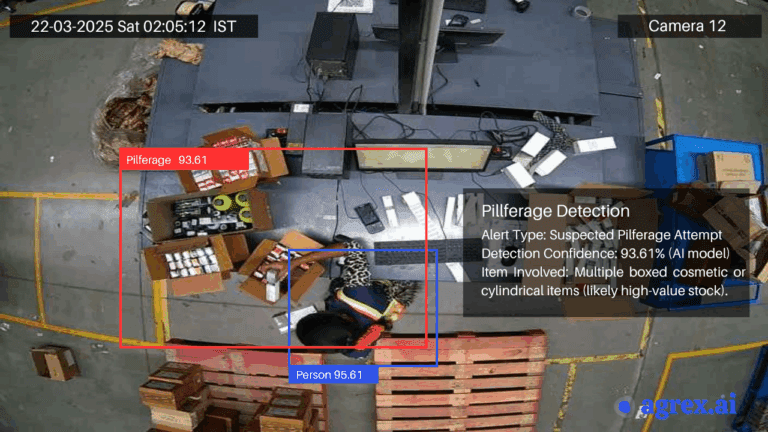

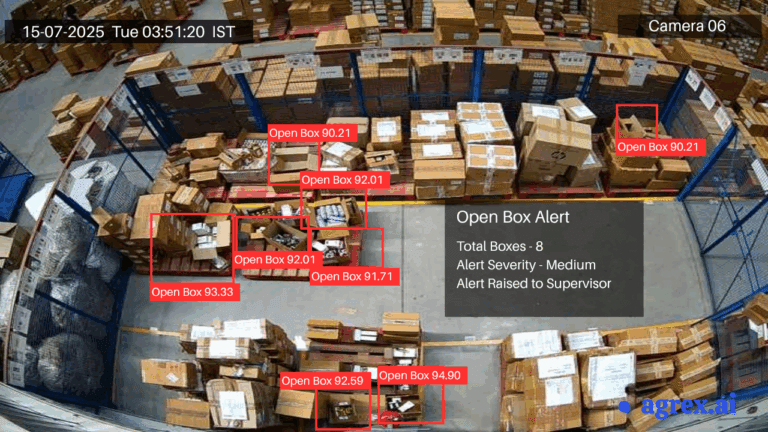

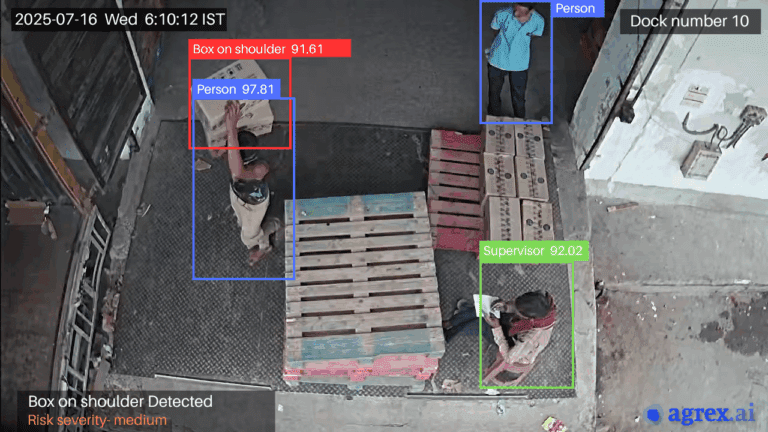

Frequent box mishandling (open boxes, throwing, standing/sitting on parcels) leading to DEPS losses

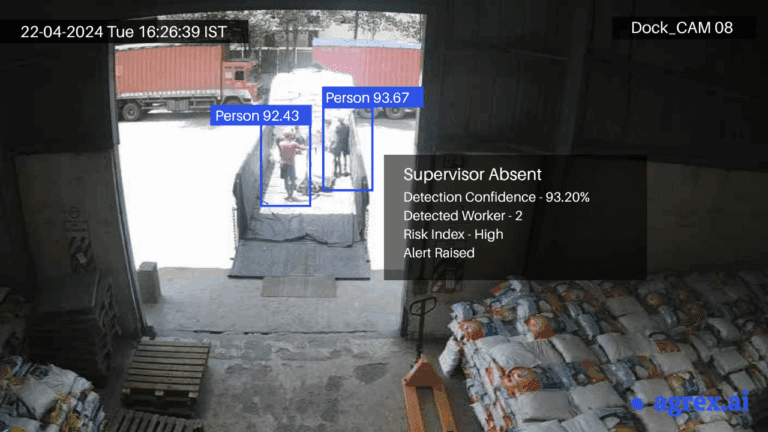

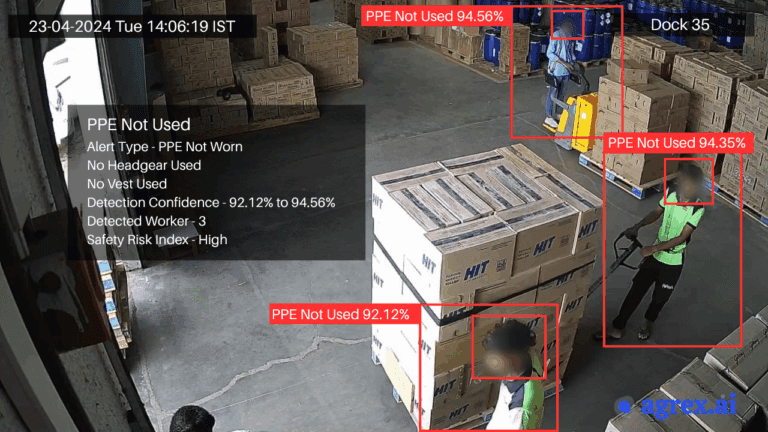

SOP non-compliance by staff such as moving packages into unauthorized zones and ignoring PPE requirements

MHE misuse, like wrong forklift parking and underutilization of BOPT units

Inefficient dock and bay management, with trucks idling or delayed in turn-around time

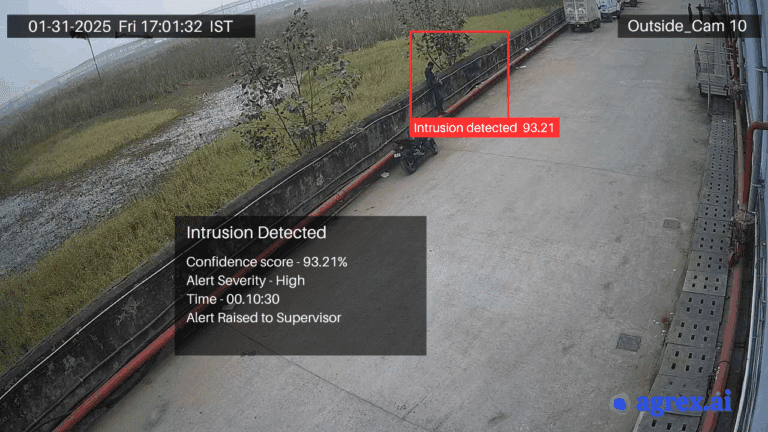

Lack of real-time fire, smoke, and intrusion detection, especially in off-hours

No visibility into camera downtime, tampering, or storage (HDD) failures, risking surveillance blind spots

With rising SLA penalties and declining customer satisfaction scores, the leadership team needed a scalable, automated solution to enforce discipline and extract actionable insights from their existing video infrastructure.

Solution

The logistics player deployed Agrex.ai’s Logistics Video Analytics Suite, integrating it with their existing CCTV systems across key hubs. The rollout included:

- AI-based violation detection for:

Parcel mishandling (open box, throwing, standing/sitting)

Unauthorized movement of boxes or pallets

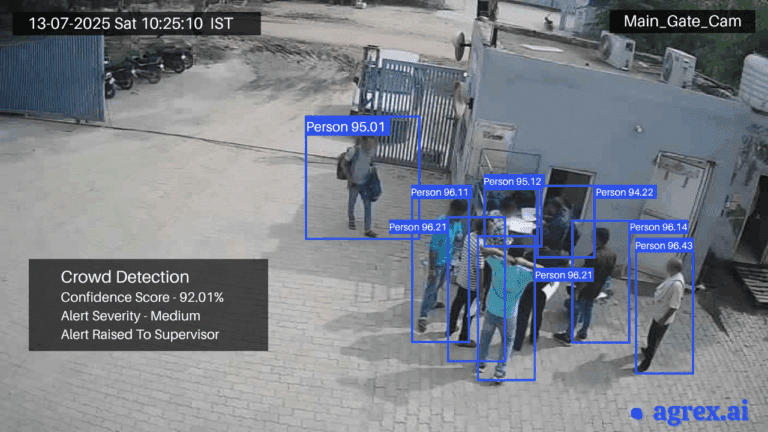

Crowd formation alerts in sensitive zones

Intrusion detection tailored to shift schedules and high-security areas

SOP & safety compliance monitoring, including:

PPE detection for gloves, vests, helmets

Blocked emergency exits and fire/smoke detection

MHE and BOPT analytics, including:

Forklift idle time, misparked MHE, and utilization heatmaps

Advanced dock analytics for:

Vehicle idle time, wait time, and turn-around time (TAT) by bay

Remote health monitoring of all surveillance equipment, tracking:

Camera/NVR online/offline status, tampering, blurred lenses, and HDD health

Outcome

In just 90 days, the operator saw measurable, cross-functional improvements:

↓ 31% DEPS losses from automated alerts on parcel abuse and unauthorized zone entry

↓ 24% truck turn-around time (TAT) from live dock analytics and bay optimization

↓ 47% fire/safety risks through real-time smoke, fire, and emergency-exit alerts

↑ 19% forklift utilization, cutting idle time and enabling smarter shift planning

↑ 22% labour productivity, aided by PPE compliance and crowd control

↑ 96% camera uptime, due to proactive remote monitoring and maintenance triggers

The result: more efficient warehouse utilization, higher SOP compliance, and a significant reduction in operational risk—all without installing new hardware.